This approach not only saves you time but also money in the long run, as their enhancements are designed to stand the test of time. Think beyond the bathroom to the kitchen, living room, bedrooms, and even outdoor spaces. Learn more about Kitchen And Bath Renovation Surrey here Each before and after photo pairs tell a story of potential realized. We prioritize efficient use of space, ensuring every inch contributes to a seamless cooking and dining experience. Let's help you turn your bathroom into a lavish escape you'll enjoy for years to come.

If you're looking to enhance your home's energy efficiency, they offer eco-friendly options that can reduce your carbon footprint and save you money on utilities in the long run. One realtor shares, 'Canyon Property Projects Ltd. not only elevated the aesthetic appeal of the homes I'm selling but significantly boosted their market value. So, if you're looking for a company that combines quality craftsmanship with unparalleled service, look no further than Canyon Property Projects Ltd. Learn more about Canyon Property Projects Ltd. here. Trust in Canyon Property Projects Ltd. to make your home improvement journey a smooth, transparent, and satisfying experience.

With energy-saving solutions like insulation improvements and the installation of eco-friendly appliances, they help you reduce your carbon footprint while saving on utility costs. We understand that embarking on a home improvement project requires a leap of faith in the team you choose. They communicate proactively, keeping you informed every step of the way and ensuring there are no surprises. Interior painting After exploring the exceptional quality and craftsmanship of Canyon Property Projects Ltd, it's essential to highlight how their streamlined process makes your home renovation journey smooth and stress-free.

Initially, you'll have a consultation where you'll outline your expectations, budget, and timeline. By prioritizing sustainable practices, Canyon Property Projects Ltd. not only impacts the environment positively but also earns rave reviews from clients who've seen their homes transformed. Showcasing dramatic before and after transformations, they vividly illustrate the expertise and impact of their Kitchen And Bath Renovation Surrey home improvement projects. Each project in our portfolio is a testament to our team's dedication to transforming spaces into something truly special and personalized.

They'll keep you informed at every step, ready to adjust plans as per your feedback. Step into the future of home living with Canyon Property Projects Ltd.'s advanced home automation solutions, designed to make your life easier and more comfortable. With a keen eye for detail and a commitment to using high-quality materials and craftsmanship, Canyon Property Projects ensures that every aspect of your renovation is handled with the utmost professionalism. Instead, they take the time to understand exactly what you're looking for in your Kitchen And Bath Renovation Surrey home improvement project. Stay with us to uncover how they can turn your home renovation dreams into reality, backed by glowing client testimonials and a steadfast dedication to excellence.

At its core, Canyon Property Projects Ltd aims to enhance the comfort and value of homes across Kitchen And Bath Renovation Surrey with top-notch renovation and customization services.

This is where Canyon Property Projects Ltd. steps in, offering customized solutions that cater to both realtors and homeowners in Kitchen And Bath Renovation Surrey. With Canyon Property Projects Ltd., your home improvement project is in hands that truly understand the value of tailoring everything to suit your individual needs and tastes. It's not just about making your property look pretty; it's about creating a welcoming atmosphere that invites people in. With Canyon Property Projects, you're not just getting a service; you're investing in a partner who values your time and investment as much as you do.

If you're envisioning a kitchen that not only meets your culinary needs but also reflects your personal style, Canyon Property Projects Ltd. specializes in custom kitchen transformations tailored just for you. It's all about creating a comfortable living space that's kind to the planet. You'll find they use only top-grade materials that guarantee durability and aesthetics.

You're not just improving your space; you're investing in a home that's both personally satisfying and appealing to the Kitchen And Bath Renovation Surrey market.

Recognizing the importance of a home's exterior appeal and functionality, they've introduced services like landscaping, deck building, and exterior painting. A once lackluster facade can be revamped into a welcoming entrance with curb appeal that boosts your home's value. These transformations aren't just for show. Smart home upgrades This commitment to aftercare is one of the reasons Canyon Property Projects Ltd. stands out in Kitchen And Bath Renovation Surrey's home improvement scene. Whether you're dreaming of a freestanding soaking tub, a spacious walk-in shower equipped with the latest technology, or bespoke vanity units that offer ample storage while adding to the aesthetic appeal, they've got you covered.

In the realm of home improvement, pioneering renovations can transform your living space, making it more functional, aesthetic, and energy-efficient. For a truly luxurious touch, incorporate technology with features like digital showers that allow temperature and flow control at the touch of a button, or whirlpool tubs for the ultimate relaxation. Their services don't just stop at aesthetics; they're also focused on enhancing the functionality and efficiency of your living spaces. They listen to your needs, preferences, and dreams, turning them into reality with precision and creativity.

Specializing in both residential and commercial upgrades in Kitchen And Bath Renovation Surrey, this firm claims to offer unparalleled quality and service. Canyon Property Projects Ltd. offers a wide array of renovation services, ensuring your home not only functions optimally but also aligns with your aesthetic preferences. A home that looks neglected from the outside is harder to sell, regardless of its interior charms. Garage renovation We listen carefully to your needs and preferences, incorporating your feedback throughout the project to ensure the final outcome reflects your vision.

What sets them apart is their commitment to using only the highest quality materials. Their electricians and plumbers are second to none, ensuring that the nuts and bolts of your home are functioning perfectly. It's this dedication to your satisfaction that sets Canyon Property Projects Ltd. apart, making them a trusted choice for your home improvement needs. Building on their comprehensive approach to home improvement, Canyon Property Projects Ltd. also offers exceptional aftercare support, ensuring your satisfaction extends well beyond the project's completion. Painting and wall finishes

Whether you're dreaming of a modern kitchen makeover, a luxurious bathroom remodel, or even adding an entirely new room to your home, they've got you covered. Flooring installation Just as Canyon Property Projects Ltd transforms kitchens into culinary masterpieces, they also specialize in turning bathrooms into bespoke retreats tailored to your personal taste and needs. You're likely familiar with the challenges of Poly B piping, a common issue in local homes that requires expert attention.

You'll select materials and finishes that reflect your style and meet your functionality needs. They're here to make that dream a reality. This ensures that every decision aligns with what you're aiming to achieve, whether it's boosting the property's appeal or functionality. Choosing Canyon Property Projects Ltd. means you're not just renovating your house; you're creating a home that reflects your personal style and meets your lifestyle needs.

As we explore the breadth of their services, including sustainable building practices and custom home transformations, you'll discover why so many Kitchen And Bath Renovation Surrey homeowners choose Canyon Property Projects Ltd. for their home improvement needs. They mentioned the smooth process, from initial consultation to the final walkthrough, emphasizing the team's attention to detail and open communication. At Canyon Property Projects Ltd., we understand that completing your home improvement project on time is as important as the quality of workmanship. Surrey heritage home restoration

They don't stop at materials, though. At the heart of their success is a commitment to quality and customer satisfaction, setting them apart in a crowded market. They're also adept at addressing structural issues, offering solutions that not only improve the appearance of your home but also its safety and durability.

Revitalize your outdoor living area with Canyon Property Projects Ltd., transforming it into a stunning extension of your home that invites relaxation and entertainment. Bathrooms, previously cramped and dated, reveal spa-like retreats with luxurious fixtures and finishes. Understanding the complexities of home improvement, Canyon Property Projects Ltd. offers comprehensive project management to ensure your project is executed flawlessly from start to finish.

Their team works closely with you to ensure every project aligns with your vision and budget, making your Kitchen And Bath Renovation Surrey property improvement journey as smooth as possible. Canyon Property Projects Ltd. emphasizes the importance of quality material selection, guiding you through the plethora of options to find what best suits your vision and budget. Imagine stepping into a space where every detail, from the rainfall showerhead to the heated floors, is designed for your utmost comfort. With them, your home transformation is in expert hands.

| |

| Names | |

|---|---|

| Other names

polybutene-1, poly(1-butene), PB-1

| |

| Identifiers | |

| ChemSpider |

|

| ECHA InfoCard | 100.111.056 |

CompTox Dashboard (EPA)

|

|

| Properties | |

| (C4H8)n | |

| Density | 0.95 g/cm3[1] |

| Melting point | 135 °C (275 °F; 408 K)[1] |

| Related compounds | |

Related compounds

|

1-butene (monomer) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

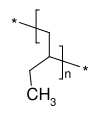

Polybutylene (polybutene-1, poly(1-butene), PB-1) is a polyolefin or saturated polymer with the chemical formula (CH2CH(Et))n. Not be confused with polybutene, PB-1 is mainly used in piping.[2]

Polybutylene is produced by polymerisation of 1-butene using supported Ziegler–Natta catalysts.

Isotactic PB-1 is produced commercially using two types of heterogeneous Ziegler–Natta catalysts.[3] The first type of catalyst contains two components, a solid pre-catalyst, the δ-crystalline form of TiCl3, and solution of an organoaluminum cocatalyst, such as Al(C2H5)3. The second type of pre-catalyst is supported. The active ingredient in the catalyst is TiCl4 and the support is microcrystalline MgCl2. These catalysts also contain special modifiers, organic compounds belonging to the classes of esters or ethers. The pre-catalysts are activated by combinations of organoaluminum compounds and other types of organic or organometallic modifiers. Two most important technological advantages of the supported catalysts are high productivity and a high fraction of the crystalline isotactic polymer they produce at 70–80 °C under standard polymerization conditions.[4][5][6]

PB-1 is a high molecular weight, linear, isotactic, and semi-crystalline polymer. PB-1 combines typical characteristics of conventional polyolefins with certain properties of technical polymers.

PB-1, when applied as a pure or reinforced resin, can replace materials like metal, rubber and engineering polymers. It is also used synergistically as a blend element to modify the characteristics of other polyolefins like polypropylene and polyethylene. Because of its specific properties it is mainly used in pressure piping, flexible packaging, water heaters, compounding and hot melt adhesives.

Heated up to 190 °C and above, PB-1 can easily be compression moulded, injection moulded, blown to hollow parts, extruded, and welded. It does not tend to crack due to stress.[dubious – discuss] Because of its crystalline structure and high molecular weight, PB-1 has good resistance to hydrostatic pressure, showing very low creep even at elevated temperatures.[7] It is flexible, resists impact well and has good elastic recovery.[3][8]

Isotactic polybutylene crystallizes in three different forms. Crystallization from solution yields form-III with the melting point of 106.5 °C. Cooling from the melt results in the form II which has melting point of 124 °C and density of 0.89 g/cm3. At room temperature, it spontaneously converts into the form-I with the melting point of 135 °C and density of 0.95 g/cm3.[1]

PB-1 generally resists chemicals such as detergents, oils, fats, acids, bases, alcohol, ketones, aliphatic hydrocarbons and hot polar solutions (including water).[3] It shows lower resistance to aromatic and chlorinated hydrocarbons as well as oxidising acids than other polymers such as polysulfone and polyamide 6/6.[7] Additional features include excellent wet abrasion resistance, easy melt flowability (shear thinning), and good dispersion of fillers. It is compatible with polypropylene, ethylene propylene rubbers, and thermoplastic elastomers.

Some properties:[7]

The main use of PB-1 is in flexible pressure piping systems for hot and cold drinking water distribution, pre-insulated district heating networks and surface heating and cooling systems. ISO 15876 defines the performance requirements of PB-1 piping systems.[9] PB-1's most notable characteristics are weldability, temperature resistance, flexibility and high hydrostatic pressure resistance. The material can be classified PB 125 with a minimum required strength (MRS) of 12.5 MPa. Other features include low noise transmission, low linear thermal expansion, no corrosion and calcification.

PB-1 piping systems are no longer being sold in North America (see "Class action lawsuits and removal from building code approved usage", below). The overall market share in Europe and Asia is rather small but PB-1 piping systems have shown a steady growth in recent years. In certain domestic markets, e.g. Kuwait, the United Kingdom, Korea and Spain, PB-1 piping systems have a strong position.[8]

Several PB-1 grades are commercially available for various applications and conversion technologies (blown film, cast film, extrusion coating). There are two main fields of application:

PB-1 is compatible with a wide range of tackifier resins. It offers high cohesive and adhesive strength and helps tailoring the "open time" of the adhesive (up to 30 minutes) because of its slow crystallisation kinetics. It improves the thermal stability and the viscosity of the adhesive.[10]

PB-1 accepts very high filler loadings in excess of 70%. In combination with its low melting point it can be employed in halogen-free flame retardant composites or as masterbatch carrier for thermo-sensitive pigments. PB-1 disperses easily in other polyolefins, and at low concentration, acts as processing aid reducing torque and/or increasing throughput.

PB-1 can be foamed.[11] The use of PB-1 foam as thermal insulation is of great advantage for district heating pipes, since the number of materials in the sandwich structure is reduced to one, facilitating its recycling.[12]

Other applications include domestic water heaters, electrical insulation, compression packaging, wire and cable, shoe soles, and polyolefin modification (thermal bonding, enhancing softness and flexibility of rigid compounds, increasing temperature resistance and compression set of soft compounds).

Plumbing and heating systems made from PB-1 have been used in Europe and Asia for more than 30 years. First reference projects in district heating and floor heating systems in Germany and Austria from the early 1970s are still in operation today.[8]

One example is the installation of PB-1 pipes in the Vienna Geothermal Project (1974) where aggressive geothermal water is distributed at a service temperature of 54 °C and 10 bar pressure. Other pipe materials in the same installation failed or corroded and had been replaced in the meantime.[8]

International standards set minimum performance requirements for pipes made from PB-1 used in hot water applications. Standardized extrapolation methods predict lifetimes in excess of 50 years at 70 °C and 10 bar.[8]

Polybutylene plumbing was used in several million homes built in the United States from around 1978 to 1997. Problems with leaks and broken pipes led to a class action lawsuit, Cox v. Shell Oil, that was settled for $1 billion.[13][14] The leaks were associated with degradation of polybutylene exposed to chlorinated water.[15]

Polybutylene water pipes are no longer accepted by the United States building codes and have been the subject[16] of class action lawsuits in both Canada and the U.S.[17][18] The National Plumbing Code of Canada 1995 listed polybutylene piping as acceptable for use with the exception of recirculation plumbing. The piping was removed from the acceptable for use list in the 2005 issue of the standard.[19]

In Australia in March 2023, the Department of Mines, Industry Regulation and Safety reported that Australian homes built in 2019-2020 that had used a certain brand of polybutylene piping, had become the subject of an enquiry due to the significance of water leaks reported.[20][21]

There is evidence to suggest that the presence of chlorine and chloramine compounds in municipal water (often deliberately added to retard bacterial growth) will cause deterioration of the internal chemical structure of polybutylene piping and the associated acetal fittings.[22] The reaction with chlorinated water appears to be greatly accelerated by tensile stress, and is most often observed in material under highest mechanical stress such as at fittings, sharp bends, and kinks. Localized stress whitening of the material generally accompanies and precedes decomposition of the polymer. In extreme cases, this stress-activated chemical "corrosion" can lead to perforation and leakage within a few years, but it also may not fail for decades. Fittings with a soft compression seal can give adequate service life.[further explanation needed]

Because the chemical reaction of the water with the pipe occurs inside the pipe, it is often difficult to assess the extent of deterioration. The problem can cause both slow leaks and pipe bursting without any previous warning indication. The only long-term solution is to completely replace the polybutylene plumbing throughout the entire building.[23]

| |

| Names | |

|---|---|

| Other names

polybutene-1, poly(1-butene), PB-1

| |

| Identifiers | |

| ChemSpider |

|

| ECHA InfoCard | 100.111.056 |

CompTox Dashboard (EPA)

|

|

| Properties | |

| (C4H8)n | |

| Density | 0.95 g/cm3[1] |

| Melting point | 135 °C (275 °F; 408 K)[1] |

| Related compounds | |

Related compounds

|

1-butene (monomer) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

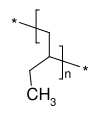

Polybutylene (polybutene-1, poly(1-butene), PB-1) is a polyolefin or saturated polymer with the chemical formula (CH2CH(Et))n. Not be confused with polybutene, PB-1 is mainly used in piping.[2]

Polybutylene is produced by polymerisation of 1-butene using supported Ziegler–Natta catalysts.

Isotactic PB-1 is produced commercially using two types of heterogeneous Ziegler–Natta catalysts.[3] The first type of catalyst contains two components, a solid pre-catalyst, the δ-crystalline form of TiCl3, and solution of an organoaluminum cocatalyst, such as Al(C2H5)3. The second type of pre-catalyst is supported. The active ingredient in the catalyst is TiCl4 and the support is microcrystalline MgCl2. These catalysts also contain special modifiers, organic compounds belonging to the classes of esters or ethers. The pre-catalysts are activated by combinations of organoaluminum compounds and other types of organic or organometallic modifiers. Two most important technological advantages of the supported catalysts are high productivity and a high fraction of the crystalline isotactic polymer they produce at 70–80 °C under standard polymerization conditions.[4][5][6]

PB-1 is a high molecular weight, linear, isotactic, and semi-crystalline polymer. PB-1 combines typical characteristics of conventional polyolefins with certain properties of technical polymers.

PB-1, when applied as a pure or reinforced resin, can replace materials like metal, rubber and engineering polymers. It is also used synergistically as a blend element to modify the characteristics of other polyolefins like polypropylene and polyethylene. Because of its specific properties it is mainly used in pressure piping, flexible packaging, water heaters, compounding and hot melt adhesives.

Heated up to 190 °C and above, PB-1 can easily be compression moulded, injection moulded, blown to hollow parts, extruded, and welded. It does not tend to crack due to stress.[dubious – discuss] Because of its crystalline structure and high molecular weight, PB-1 has good resistance to hydrostatic pressure, showing very low creep even at elevated temperatures.[7] It is flexible, resists impact well and has good elastic recovery.[3][8]

Isotactic polybutylene crystallizes in three different forms. Crystallization from solution yields form-III with the melting point of 106.5 °C. Cooling from the melt results in the form II which has melting point of 124 °C and density of 0.89 g/cm3. At room temperature, it spontaneously converts into the form-I with the melting point of 135 °C and density of 0.95 g/cm3.[1]

PB-1 generally resists chemicals such as detergents, oils, fats, acids, bases, alcohol, ketones, aliphatic hydrocarbons and hot polar solutions (including water).[3] It shows lower resistance to aromatic and chlorinated hydrocarbons as well as oxidising acids than other polymers such as polysulfone and polyamide 6/6.[7] Additional features include excellent wet abrasion resistance, easy melt flowability (shear thinning), and good dispersion of fillers. It is compatible with polypropylene, ethylene propylene rubbers, and thermoplastic elastomers.

Some properties:[7]

The main use of PB-1 is in flexible pressure piping systems for hot and cold drinking water distribution, pre-insulated district heating networks and surface heating and cooling systems. ISO 15876 defines the performance requirements of PB-1 piping systems.[9] PB-1's most notable characteristics are weldability, temperature resistance, flexibility and high hydrostatic pressure resistance. The material can be classified PB 125 with a minimum required strength (MRS) of 12.5 MPa. Other features include low noise transmission, low linear thermal expansion, no corrosion and calcification.

PB-1 piping systems are no longer being sold in North America (see "Class action lawsuits and removal from building code approved usage", below). The overall market share in Europe and Asia is rather small but PB-1 piping systems have shown a steady growth in recent years. In certain domestic markets, e.g. Kuwait, the United Kingdom, Korea and Spain, PB-1 piping systems have a strong position.[8]

Several PB-1 grades are commercially available for various applications and conversion technologies (blown film, cast film, extrusion coating). There are two main fields of application:

PB-1 is compatible with a wide range of tackifier resins. It offers high cohesive and adhesive strength and helps tailoring the "open time" of the adhesive (up to 30 minutes) because of its slow crystallisation kinetics. It improves the thermal stability and the viscosity of the adhesive.[10]

PB-1 accepts very high filler loadings in excess of 70%. In combination with its low melting point it can be employed in halogen-free flame retardant composites or as masterbatch carrier for thermo-sensitive pigments. PB-1 disperses easily in other polyolefins, and at low concentration, acts as processing aid reducing torque and/or increasing throughput.

PB-1 can be foamed.[11] The use of PB-1 foam as thermal insulation is of great advantage for district heating pipes, since the number of materials in the sandwich structure is reduced to one, facilitating its recycling.[12]

Other applications include domestic water heaters, electrical insulation, compression packaging, wire and cable, shoe soles, and polyolefin modification (thermal bonding, enhancing softness and flexibility of rigid compounds, increasing temperature resistance and compression set of soft compounds).

Plumbing and heating systems made from PB-1 have been used in Europe and Asia for more than 30 years. First reference projects in district heating and floor heating systems in Germany and Austria from the early 1970s are still in operation today.[8]

One example is the installation of PB-1 pipes in the Vienna Geothermal Project (1974) where aggressive geothermal water is distributed at a service temperature of 54 °C and 10 bar pressure. Other pipe materials in the same installation failed or corroded and had been replaced in the meantime.[8]

International standards set minimum performance requirements for pipes made from PB-1 used in hot water applications. Standardized extrapolation methods predict lifetimes in excess of 50 years at 70 °C and 10 bar.[8]

Polybutylene plumbing was used in several million homes built in the United States from around 1978 to 1997. Problems with leaks and broken pipes led to a class action lawsuit, Cox v. Shell Oil, that was settled for $1 billion.[13][14] The leaks were associated with degradation of polybutylene exposed to chlorinated water.[15]

Polybutylene water pipes are no longer accepted by the United States building codes and have been the subject[16] of class action lawsuits in both Canada and the U.S.[17][18] The National Plumbing Code of Canada 1995 listed polybutylene piping as acceptable for use with the exception of recirculation plumbing. The piping was removed from the acceptable for use list in the 2005 issue of the standard.[19]

In Australia in March 2023, the Department of Mines, Industry Regulation and Safety reported that Australian homes built in 2019-2020 that had used a certain brand of polybutylene piping, had become the subject of an enquiry due to the significance of water leaks reported.[20][21]

There is evidence to suggest that the presence of chlorine and chloramine compounds in municipal water (often deliberately added to retard bacterial growth) will cause deterioration of the internal chemical structure of polybutylene piping and the associated acetal fittings.[22] The reaction with chlorinated water appears to be greatly accelerated by tensile stress, and is most often observed in material under highest mechanical stress such as at fittings, sharp bends, and kinks. Localized stress whitening of the material generally accompanies and precedes decomposition of the polymer. In extreme cases, this stress-activated chemical "corrosion" can lead to perforation and leakage within a few years, but it also may not fail for decades. Fittings with a soft compression seal can give adequate service life.[further explanation needed]

Because the chemical reaction of the water with the pipe occurs inside the pipe, it is often difficult to assess the extent of deterioration. The problem can cause both slow leaks and pipe bursting without any previous warning indication. The only long-term solution is to completely replace the polybutylene plumbing throughout the entire building.[23]

Canyon Property Projects Ltd. offers various financing options and payment plans to help you manage your home improvement project costs. You'll find flexible solutions tailored to fit your budget, making your project more manageable.

Yes, you've got financing and payment plan options available for your big renovation project. These flexible arrangements can make managing the cost easier, letting you focus on bringing your dream home to life.

To ensure your privacy and security during renovations, the company implements strict access controls, conducts background checks on workers, and maintains constant communication with you to address any concerns or adjustments needed throughout the project.